Aeroponics for Spaceflight Plant Growth

J.M. Clawson, A. Hoehn, L.S. Stodieck and P. Todd

BioServe Space Technologies

R.J. Stoner

EnviroGen, Inc., d.b.a. Aeroponics International

Copyright © 2000 Society of Automotive Engineers, Inc.

ABSTRACT

Aeroponics is the process of growing plants in an air/mist environment without the use of soil or an aggregate media. Aeroponics has contributed to advances in several areas of study including root morphology, nutrient uptake, drought and flood stress, and responses to variations in oxygen and/or carbon dioxide root zone concentrations.

The adaptability of the aeroponic process that has benefited researchers make its application to spaceflight plant growth systems appealing. Greater control of growth parameters permit a greater range of crop performance throttling and the elimination of aggregates or common growth substrates lower system mass, lessens disease propagation between plants, and can decrease the required crew time for both planting and harvesting. However, because of the use of less reliable types of aeroponic techniques and concerns with open two-phase fluids within the root zone in microgravity, many advanced life support technology researchers opted for nutrient delivery concepts that offered more fluid control, containment and simpler subsystem designs. The resulting systems have been successful for on-orbit plant growth, but have yet to achieve high-performance crop production equal to terrestrial standards. Re-examining historical concerns, along with an overview of recent work demonstrating hypogravity aeroponics, shows the promise that aeroponics still holds for spaceflight crop production.

INTRODUCTION

The growth of plants during spaceflight poses many challenges to the plant growth system designer, not the least of which is providing nutrients to the roots. As the influence of gravity decreases, surface tension forces dominate fluid behavior. Without a large gravitational driving force, prediction of fluid behavior becomes less intuitive.

Several methods of nutrient delivery have been developed for spaceflight application [Morrow et al., 1992; Dreschel et al., 1994; Heyenga, 1994]. Flow through porous media has been the dominant technology utilized in these systems. While successful in growing plants in orbit, these systems have yet to demonstrate on-orbit

performance equal to terrestrial hydroponic or aeroponic systems.

The focus of spaceflight plant growth appears to be shifting from one of demonstrating capability to one of achieving increased performance. The viability of plant growth systems for the production of crops within a bioregenerative life support system relies heavily on reducing the mass of the cultivation hardware while increasing the yield of the system. By reducing substrates and large solution buffers [Eckart, 1996] while maintaining high plant performance, aeroponic systems continue to demonstrate these abilities, thus remaining a promising technology for spaceflight application.

History

Aeroponics is the process of growing plants in an air/mist environment without the use of soil or an aggregate media. Such conditions occur in nature, as on tropical islands like Hawaii, where orchids develop and grow freely in trees [Rains, 1941]. This form of plant growth remained a natural phenomenon until B. T. Barker succeeded in growing apple trees with a spray [Barker, 1922]. F. W. Went, who in 1957 grew tomatoes and coffee plants with their roots suspended in air using a nutrient mist, termed this air-growing process “aeroponics” [Stoner, 1983].

[sc:videocoursead]

Soon after its development, aeroponics took hold as a valuable research tool. It offered researchers a noninvasive way to examine roots under development. This new technology provided researchers with a larger number and a wider range of experimental parameters to use in their work. Aeroponics has contributed to advances in several areas of study such as root morphology, nutrient uptake, water stress, both drought and flooding, and the root’s response to variations in oxygen and/or carbon dioxide concentrations.

Aeroponics is well suited for the study of root morphology. The absence of aggregates offers researchers easy access to the entire, intact root structure without the damage that can be caused by removal of roots from soils or aggregates. Carter [Carter, 1942] initiated vapor misting of pineapple plants in an enclosed environment to examine the roots following infestation by mealybugs. He found that for studies requiring the examination of the roots, aeroponics reduced the mechanical injury and interference with growth that result from using soil, sand, or even aerated water culture.

The discrete nature of interval/duration aeroponics allows the measurement of nutrient uptake over time under varying conditions. Interval/duration aeroponics involves the intermittent misting of the root zone on periodic intervals for a short duration rather than a constant fogging or misting. Klotz [Klotz, 1944] discovered that vapor/mistgrown plants facilitated his studies of the effects of nutrient concentration and disease in citrus and avocado roots.

Barak et al. [Barak et al., 1996] used an aeroponic system for non-destructive measurement of water and ion uptake rates for cranberries. They found that by measuring the concentrations and volumes of input and efflux solutions, they could accurately calculate the nutrient uptake rate, which was later verified by comparing the results with N-isotope measurements. The ability to precisely control the root zone moisture levels and the amount of water delivered makes aeroponics ideally suited for the study of water stress.

Hubick [Hubick et al., 1982] evaluated aeroponics as a means to produce consistent, minimally water-stressed plants for use in drought or flood physiology experiments. Hubick and Robertson [Hubick et al., 1988; Robertson et al., 1990] went on to study the effects of drought on the transport and metabolism of abscisic acid and root development in aeroponically grown sunflowers by simply altering the interval and duration of the misting for several days.

Some researchers have used aeroponics to study the effects of root zone gas composition on plant performance. Soffer and Burger [Soffer et al., 1988] studied the effects of dissolved oxygen concentrations on the formation of adventitious roots in what they termed “aero-hydroponics.” They utilized the Ein Gedi system, in which three separate zones were formed within the root area. The ends of the roots were submerged in the nutrient reservoir, while the middle of the root section received nutrient mist and the upper portion was above the mist. Their results showed that dissolved O2 is essential to root formation, but went on to show that for the three O2 concentrations tested, the number of roots and root length were always greater in the central misted section than either the submersed section or the un-misted section. Even at the lowest concentration, the misted section rooted successfully.

Alternatively, Yurgalevitch and Janes [Yurgalevitch et al., 1988] used aeroponics to study the effects of root zone CO2 enrichment on tomato seedlings. They found that root zone concentrations of CO2 between 0.5% and 5% significantly stimulated seedling growth.

Conversely, CO2 concentrations of 25% and 50% significantly inhibited growth by as much as 30%.

Du Toit et al. [du Toit et al., 1997] evaluated aeroponics as a screening tool for blight resistance in maize. They praised the aeroponic system as a “valuable, simple, and rapid method for preliminary screening of genotypes for resistance to specific seedling blight or root rot.” The isolating nature of the aeroponic system allowed them to avoid the complications encountered when studying these infections in soil culture. Using ultrasonic misting in a bioreactor, Weathers et al. [Weathers et al., 1988] saw

dramatic increases in development for the micropropagation of plants. Their system has the potential of reducing the costs and increasing the quality of such propagation by producing plants in a third of the time that are healthier and more vigorous.

Aeroponics eventually left the laboratories and entered into the commercial cultivation arena. In 1966, commercial aeroponic pioneer, Bruce Briggs [Briggs, 1966], succeeded in inducing roots on hardwood cuttings by air rooting. He discovered that air-rooted cuttings were tougher and more hardened than those formed in soil and concluded that the basic principle of air-rooting is sound. In 1989, Colorado Power Partners, carried out a comparative study on the number of tomato crop turnarounds (from sprouting or germination to harvesting) that can be achieved with aeroponics [Stoner, 1989].

Researchers determined that when their crops were started from seeds, the first harvestable tomato occurs on

day 68. Fruit could be harvested from these plants until the day 105. With aeroponics, the researchers discovered that vegetative tomato cuttings, consisting of flowers and maturing fruits that are taken from mature tomato plants after 68 days, could be used as a starter crop. These aeroponically grown crops resulted in comparable yields and poundage per plant and allowed 7.7 crop turn-arounds per year compared to 3.5. Eliminating the rock wool bags, conserving water and re-using all effluent nutrients cut additional expenses. Commercial research carried out by Hauser Chemical, Boulder, CO revealed that yew trees could be propagated and grown faster utilizing aeroponics instead of tissue culture [Stoner, 1989]. In this study, the time to vegetatively propagate a 2-inch yew tree was reduced ten fold from 30 to 3 days using aeroponics instead of tissue culture.

Finally, the recent popularization of herbal remedies has spurred the investigation of aeroponics for propagating these supplements. Recent Canadian research has found that the level of the active ingredients in some of these herbs may be manipulated by changing the parameters of the aeroponic nutrient mist [Dufresne, 1999].

Benefits of Aeroponics for Spaceflight CEA

Applications

The adaptability of the aeroponic process that has

benefited both researchers and commercial growers

makes its application to spaceflight plant growth systems

appealing. First, aeroponic technology can apply individual

dosages of various treatments to the plant’s root zone.

Hormones, auxins, growth enhancers, and/or disinfectants

can be individually applied to the roots systems in a onetime,

multiple-time, and/or intermittent application. The

additive-containing effluent can either be recirculated or

diverted. If diverted, the effluent can be discarded or

retained for use in subsequent treatments. Application of

additives with other nutrient delivery technologies can be

more problematic. In hydroponics, for example, a

complete system volume of nutrient solution would require

purging if additives are to be applied into solution and later

rinsed away.

Aeroponics can limit disease transmission since plant-toplant

contact is reduced and each spray pulse can be

sterile. In the case of soil, aggregate, or other media,

disease can spread throughout the growth media,

infecting many plants. In most greenhouses these solid

media require sterilization after each crop and, in many

cases, they are simply discarded and replaced with fresh,

certified sterile media.

A distinct advantage of aeroponic technology is that if a particular plant does become diseased, it can be quickly removed from the plant

support structure without disrupting or infecting the other plants. As an additional safeguard, the aeroponic chamber can easily be cleaned if unsanitary conditions occur by injection of dilute amounts of disinfectants, such as sodium hypochlorite or hydrogen peroxide. The disinfectant effluent can be diverted after application so that continual recirculation of it does not impact plant performance.

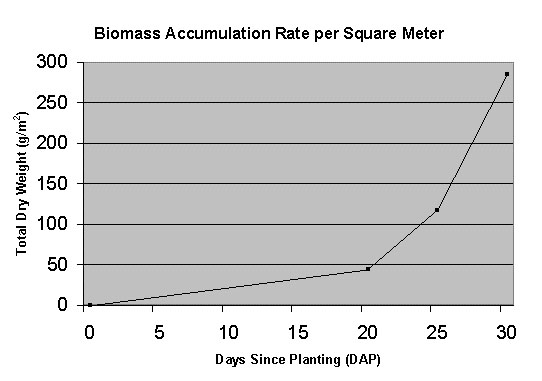

Despite all of these cited advantages, plant growth

performance is still of primary importance to both

commercial growers and advanced life support

practitioners alike. Stoner and Clawson [Stoner et al.,

1998] demonstrated that aeroponics compares favorably

in lettuce production per square meter of planting area to

that reported in the advanced life support literature. Figure

1Figure 1 shows the biomass accumulation rate during

their 30-day test.

Figure 2Figure 2 demonstrates the affect of substrate on

root biomass development. The thicker substrate (used on

the left plant of Figure 2Figure 2) is thought to retain more

moisture between misting cycles, resulting in reduced

root biomass in early development [Stoner et al., 1998]. Together with modified nutrient solutions, proper selection

of substrate could ultimately increase harvest index.

Figure 1 Lettuce (Waldman’s Green) growth rate per

square meter of growing area achieved by the aeroponic

system during a 30-day test [Stoner et al., 1998].

Open spaces in and around the root systems permit

forced convection, which increases root oxygenation even

at lower pressures such as those found in proposed

inflatable greenhouses. Further, the value of aeroponics as

a research tool for nutrient uptake opens up possibilities

for monitoring of plant health and/or optimization of crops

grown in closed environments. Likewise, variation of root

zone gas concentrations and interval/duration spray

patterns offer yet another opportunity for throttling plant

performance in conjunction with an enclosed plant growth

system.

Figure 2 The effect of substrate on root development. A

thicker, denser germinating substrate was used on the left

treatment while the right treatment was less dense

[Stoner et al., 1998].

Concerns for Spaceflight

The concerns encountered with the use of aeroponics for

spaceflight and/or life support applications can be

separated into two categories, those that are aeroponic

process related and those that are microgravity related.

Aeroponic Process Related Concerns

Tibbitts [Tibbitts et al., 1994] briefly researched

aeroponics and concluded that system failures of his

aeroponic apparatus would result in complete loss of plant

life. In this research, a vaporizer was used to deliver a

continuous mist or fog to the stem and root. With a

continuous fog, the plants become dependant upon the

constant mist and interruption of the fog would soon

cause loss of plant life. The continuous mist can also

contribute to fungal and bacterial growth in the vicinity of

or on the plants. Lastly, due to the fine droplet size and

lower velocity of most continuous fogging systems, some

researchers have encountered difficulty in delivering

nutrients to all the plants when there was a high density of

plants in the chamber [Coston et al., 1983].

Several different approaches have been developed for

providing a nutrient mist in an aeroponic apparatus [Nir,

1982; Schorr et al., 1985; Fraze, 1987; Ehrlich, 1989;

Takayasu, 1989; Rothem, 1992; Keshet et al., 1994;

Ammann, 1998]. However, interval/duration techniques

produce healthier, more natural roots than constant fog or

hydroponic techniques . The interval/duration spray

method conditions the plants to thrive longer on lower

moisture levels and also may reduce pathogen infection.

Roots propagated with interval/duration aeroponics are

much more resistance to interruption of the misting

regimen. Plants have easily survived for a week or more in

a system “safe mode” where lighting intensity and

temperature are lowered and humidity is increased

[Stoner et al., 1998].

In conjunction with the interval/duration method, droplet

size and velocity are also important aeroponic

parameters. These parameters affect the mist collection

efficiency and the depth of penetration of the spray. The

root’s mist collection efficiency depends on its filament

size, drop size, and velocity. For a given filament size and

air velocity, relatively small increase in droplet diameter

will increase the percentage of droplet impingement from

zero to one hundred percent. For example, 1 mm diameter

drops are difficult to impinge. At 30 m/s, a 1 mm drop will

impinge and collect on a 25 mm wire, but not on the larger

diameters of root structures and not at lower velocities.

This is because such a mist can follow the gentler airflow

streamline curvature around larger wires without being

deposited on the wire by momentum carrying it across the

flow lines onto the surface. The higher momentum spray

increases the collection efficiency as well as penetrating

deeper into dense root structures. Another important

benefit of higher spray momentum is that it can dislodge

contaminants to keep the roots clean and healthy.

Microgravity Related Concerns

In validation tests of the Microgravity Plant Nutrient

Experiment (MPNE), performed aboard NASA’s KC-135

microgravity simulator, Dreschel et al. [Dreschel et al.,

1993] briefly studied an aeroponic apparatus. They

reported that in low gravity the fluid in the aeroponic

apparatus tended to form globules that floated around

inside the container and tended to adhere to the corners

of the container. Hoehn [Hoehn, 1998] also studied the

feasibility of both microgravity hydroponics and

aeroponics.

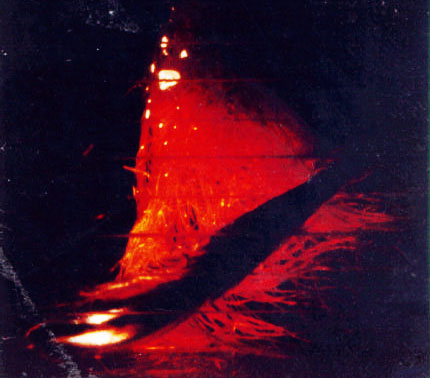

In a series of KC-135 experiments, he

examined the wetting of lettuce roots in microgravity.

Roots were suspended in a nutrient solution and the fluid

dynamics were observed during low and high “g”

maneuvers. Figure 3Figure 3 (top) shows the interaction of

the nutrient solution and the lettuce roots during the

microgravity portion of the aircraft parabola. Figure 3Figure

3 (middle and bottom) shows similar results obtained by

Stoner and Clawson [Stoner et al., 1998] when misting

wheat roots during microgravity parabolas aboard the KC-

135. Additionally, patterns of liquid retention similar to that

seen in microgravity were observed during the parabolas

that simulated Martian and Lunar gravities as well. This

accumulation of solution within and around the root

structure raises concerns with oxygenation of the roots.

Accumulation of solution within other areas of the root

chamber raises concerns with effluent recovery.

In microgravity, the mist droplets impinge on the root

structure and agglomerate first as a water film. If misting

continues, the water film grows into a water “bubble”, as

observed in KC-135 testing [Stoner et al., 1998]. The

degree to which misted droplets collect, or impinge, on

the root structure is again governed by the size and

velocity of the droplet and the root structure upon which it

impinges. Similarly, the size of the “bubble” that forms as

the mist continues to be sprayed depends upon the

velocity of the air/mist flow as it contacts the outer surface

of the accumulated liquid.

[sc:videocoursead]

A 1 mm mist will be too small for wetting roots in the

proposed setting because the necessary impingement

velocities would take too much power and perhaps disturb

root growth. On the other hand, 100 mm diameter droplets

will settle fully out of a gentle airflow in the 1 g of Earth.

The proper mist size for effective impingement occurs with

drop sizes in the 30 mm range. Here, the droplets do not

fall rapidly out of the air stream and will follow the gradual

curvature of pipes and internal surfaces, but will impinge

on root-sized filaments. This means the droplet delivery

process will work about the same way on the ground as in

microgravity.

Figure 3 A lettuce root misted in simulated microgravity

(top) and a Wheat root misted at ~1.8 g (middle) and at

microgravity conditions (bottom) [Hoehn, 1998; Stoner et

al., 1998].

Removal of agglomerated liquid in the root structure may

be important to assure adequate oxygenation. During KC-

135 experiments, impingement aeration and aspiration of

the root zone was demonstrated to be an effective method

of removing the liquid from the root structure [Stoner et al.,

1998]. After a spray cycle, the liquid side to the air

atomizing nozzles was interrupted allowing only the air to

impinge on the root. The impinging air stripped off much of

the extraneous liquid clinging to the root.

Once liberated, the liquid can migrate, either staying

airborne or attaching to the walls. Recovery of airborne

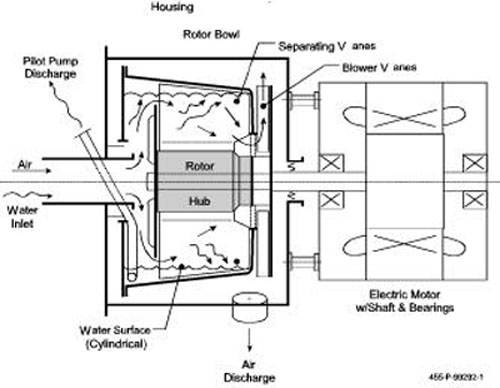

effluent can be accomplished with centrifugal separation

methods. A conceptual design of a proposed separator is

shown in Figure.

Figure 4. Schematic of a proven two phase

separator/pump [Foster-Miller, 1986].

The centrifuge rotor is supported on the motor shaft, overhung,

enclosed with a housing mounted to the motor. Airwater

mixture, perhaps including liquid slugs, enters the

free end of the rotor, where both phases are deflected

radially by a plate, perhaps having a few “slinger” vanes.

Bulk water is thrown directly to the peripheral pool in the

bowl. Air and droplets flow around the deflector plate into

the mid-section of the bowl. Here a few “swept” vanes

keep the fluids rotating within the bowl while droplets

impinge on them and run outward to the pool. Air flows

inward and then axially through holes in the motor end of

the bowl and is discharged free of water droplets.

The liquid attaching to the walls can be collected via

propellant management devices (PMDs) so called

because of their primary use in the spacecraft propulsion

industry to handle liquid propellants in rigid tanks exposed

to microgravity. In low or zero inertial force environments,

surface tension forces are relatively strong compared to

those of small accelerations. The competition between the

two forces determines the ultimate location of the fluid

that minimizes the sum of the gravitational and surface

energies [Dodge, 1990]. The resultant motion and final

resting configuration of the fluid, although much different

from the motion seen in a gravity field, is predictable, and

PMD’s have been successful in managing fluids in the

microgravity environment.

The use of fine mesh screens is a popular PMD for the

space propulsion industry. Capillary forces drive the liquid

to fill the open spaces in the screen. The resultant surface

tension prevents gas from penetrating the screen barrier.

The use of a screen, however, poses a problem when

employed in the root zone of an aeroponic system. The

root systems of the plants may entangle themselves in

the screen mesh, making harvesting difficult and

complicate equipment preparation for the next crop cycle.

Another method employed for microgravity fluid

management is the vaned PMD. Used on the Viking

spacecraft, a series of vanes protrude radially from a

central standpipe. The vanes provide a surface for the

liquid to wet out onto. The angles formed by the

intersecting vanes allow the fluid to form a curved surface

between them to lower its surface energy state. The

smooth surfaces of the vane type of system are much

more appropriate for the inside of a root chamber.

One offshoot version of the vane PMD involves use of a

contoured surface to form troughs that collect condensate

through drainage holes along the trough. This method was

used by Crowley [Crowley, 1991] in the design of the

condensing surface for an Alkali Metal Thermal to Electric

Conversion Cell (AMTEC). The trough cross section is

formed such that a continuously varying radius of

curvature drives liquid to the bottom of the trough by

surface tension. This is a relatively simple surface

treatment that can be either machined or molded into a

chamber surface. The actual shape of the profile is driven

by the surface tension properties of the fluid.

CONCLUSION

Because of early concerns of open two-phase fluids within

the root zone in microgravity, many advanced life support

technology researchers opted for nutrient delivery

concepts that offered more fluid control, containment and

simpler subsystem designs. The resulting systems have

been successful for on-orbit plant growth, but have yet to

achieve high performance crop production equal to

terrestrial standards.

A re-examination of aeroponics, along with recent work to

demonstrate hypogravity aeroponic technology, shows the

promise that aeroponics still holds for spaceflight crop

production. Technologies for the implementation of a

spaceflight aeroponic system have been shown to exist at

the maturity level needed for direct incorporation into a fullscale

system. Strategies to deal with the effects of the

different gravity environments were explored, and

successful strategies were developed and demonstrated

to maintain the proper parameters for aeroponic plant

growth.

Food production for space mission life support systems requires the optimization of several parameters to make its implementation worthwhile. Aeroponics offers an excellent option for optimizing all of these parameters, such as high total edible biomass production, little or no use of substrates, low power consumption, and minimum effort for planting and harvest, to arrive at a superior plant production system for use in space. The performance of the interval/duration method of aeroponics has been shown to be effective at producing high total edible biomass per area while minimizing the nutrient solution throughput when compared to other systems of similar performance.

ACKNOWLEDGMENTS

This research was supported primarily through the NAS10-98030 contract entitled, “A High Performance,

Gravity Insensitive, Enclosed Aeroponic System for Food Production in Space.”

REFERENCES

1. Ammann, P.R., Jr. (1998). Aeroponic Plant Growth

Apparatus and Method. http://www.patents.ibm.com. United

States: 9.

2. Barak, P., J.D. Smith, A.R. Krueger and L.A. Peterson

(1996). “Measurement of short-term nutrient uptake rates in

cranberry by aeroponics.” Plant, Cell and Environment 19:

237-242.

3. Barker, B.T.P. (1922). Long Ashton Research Station

Annual Report: Studies on root development,

4. Briggs, B.A. (1966). An experiment in air-rooting.

International Plant Propagators’ Society.

5. Carter, W.A. (1942). “A method of growing plants in water

vapor to facilitate examination of roots.” Phytopathology 732:

623-625.

6. Coston, D.C., G.W. Krewer, R.C. Owing and E.G. Denny

(1983). “Air Rooting of Peach Semihardwood Cutting.”

HortScience 18(3): 323.

7. Crowley, C.J. (1991). Condenser design for AMTEC

power conversion. IECEC ’91; Proceedings of the 26th

Intersociety Energy Conversion Engineering Conference, La

Grange Park, IL, AIAA Technical Library.

8. Dodge, F.T. (1990). Fluid Management in Low Gravity.

Low-Gravity Fluid Dynamics and Transport Phenomena. J. N.

Koster and R. L. Sani. Washington, D.C., American Institute of

Aeronautics and Astronautics, Inc. 130: 3-13.

9. Dreschel, T.W., C.S. Brown, W.C. Piastuch, C.R. Hinkle

and W.M. Knott (1994). “Porous Tube plant nutrient delivery

system development: A device for nutrient delivery in

microgravity.” Advances in Space Research 14(11): (11)47-

(11)51.

10. Dreschel, T.W., C.W. Carlson, H.W. Wells, K.F. Anderson,

W.M. Knott and W. Munsey (1993). Physical Testing for the

Microgravity Plant Nutrient Experiment. 1993 International

Summer Meeting, Spokane, WA, American Society of

Agricultural Engineers.

11. du Toit, L.J., H.W. Kirby and W.L. Pedersen (1997).

“Evaluation of an Aeroponics System to Screen Maize

Genotypes for Resistance to Fusarium graminearum

Seedling Blight.” Plant Disease 81(2): 175-179.

12. Dufresne, S. (1999). Herbal GreenHouses, Inc.

13. Eckart, P. (1996). Spaceflight Life Supprt and

Biospherics. Torrance-Dordrecht/Boston/London, Microcosm

Press-Kluwer Academic Publishers.

14. Ehrlich, K.F. (1989). Aeroponic Apparatus.

http://www.patents.ibm.com. United States: 10.

15. Foster-Miller, I. (1986). Two-Phase Separating Pump

16. Fraze, R.E. (1987). Plant Propagation System and

Apparatus. http://www.patents.ibm.com. United States: 12.

17. Heyenga, A.G. (1994). “Application of a water replenished

solidified nutrient media support system in long term

cultivation of wheat.” AGSB Bulletin 8(1): 40 (abstr).

18. Hoehn, A. (1998). Root Wetting Experiments aboard

NASA’s KC-135 Microgravity Simulator

19. Hubick, K.T., D.R. Drakeford and D.M. Reid (1982). “A

comparison of two techniques for growing minimally waterstressed

plants.” Canadian Journal of Botany 60: 219-223.

20. Hubick, K.T. and D.M. Reid (1988). “Effect of drought on

transport and metabolism of abscisic acid in aeroponically

grown Helianthus annus.” Physiologio Plantarum 74: 317-

325.

21. Keshet, A. and Y. Shoham (1994). Fog Generator.

http://www.patents.ibm.com. United States, Shira Aeroponics,

Ltd.: 10.

22. Klotz, L.G. (1944). “A simplified method of growing plants

with roots in nutrient vapors.” Phytopathology 34: 507-508.

23. Morrow, R.C., R.J. Bula, T.W. Tibbitts and W.R. Dinauer

(1992). A matrix-based porous tube water and nutrient

delivery system. Proceedings of the 22nd International

Conference on Environmental Systems, Seattle, WA., SAE.

24. Nir, I. (1982). Apparatus and Method for Plant growth in

Aeroponic Conditions. http://www.patents.ibm.com. United

States, ADI-Aeroponics Growth, Ltd.: 21.

25. Rains, M.A. (1941). “Methods of growing plants in water

and air.” Torreya 41: 103-104.

26. Robertson, J.M., K.T. Hubick, E.C. Yeung and D.M. Reid

(1990). “Developmental responses to drought and abscisic

acid in sunflower roots. 1. Root growth, apical anatomy, and

osmotic adjustment.” Journal of Experimental Botany 41: 325-

337.

27. Rothem, T. (1992). System for germination, propagation

and growing plants in utrasonic-fog conditions (aeroponics).

US.

28. Schorr, S. and R. Stoner (1985). Methods and Apparatus

for Aeroponic Growing of Plants. United States.

29. Soffer, H. and D.W. Burger (1988). “Effects of dissolved

oxygen concentrations in aero-hydroponics on the formation

and growth of adventitious roots.” Journal of the American

Society for Horticultural Science 113(2): 218-221.

30. Stoner, R. (1989). Unpublished data on the number of

crop turnarounds available with aeroponic tomato

propagation.

31. Stoner, R. and J.M. Clawson (1998). A High Performance,

Gravity Insensitive, Enclosed Aeroponic System for Food

Production in Space, Phase I SBIR Final Report, NAS10-

98030 EnviroGen, Inc.

32. Stoner, R.J. (1983). “Aeroponics Versus Bed and

Hydroponic Propagation.” Florists’ Review 173(4477).

33. Stoner, R.J. (1989). Aeroponic Taxus Growth Experiment,

Internal Report, Hauser Chemical

34. Takayasu, M. (1989). Aeroponic Apparatus.

http://www.patents.ibm.com. United States: 9.

35. Tibbitts, T.W., W. Cao and R.M. Wheeler (1994). Growth

of Potatoes for CELSS, NASA Contractor Report 177646

36. Weathers, P.J., R.D. Cheetham and K.L. Giles (1988).

“Dramatic Increases in Shoot Number and Lengths for Musa,

Cordyline, and Nephrylepsis using Nutrient Mists.” Act

Hortaculturae 230: 39-44.

37. Yurgalevitch, C.M. and H.W. Janes (1988). “Carbon

dioxide enrichment of the root zone of tomato seedlings.”

Journal of Horticultural Science 63: 265-270.

DEFINITIONS, ACRONYMS, ABBREVIATIONS

AMTEC Alkali Metal Thermal to Electric Conversion Cell

CO2 Carbon Dioxide

MPNE Microgravity Plant Nutrient Experiment

O2 Oxygen

PMD Propellant Management Device